Foundries generally have a very hot working environment because of the furnaces and molten metal. The molds and core heating, the ladles preheating and the heat treatment of metal castings make additional sources of heat. Personnel employed in furnace or ladle slagging and those executing tasks in close proximity to the molten metal, including furnace workers, welders, arc-air operators, oxy-cutters and crane operators, are most vulnerable to severe heat effects.

Foundries generally have a very hot working environment because of the furnaces and molten metal. The molds and core heating, the ladles preheating and the heat treatment of metal castings make additional sources of heat. Personnel employed in furnace or ladle slagging and those executing tasks in close proximity to the molten metal, including furnace workers, welders, arc-air operators, oxy-cutters and crane operators, are most vulnerable to severe heat effects.

The human body functions normally within 1° C to 1.5° C of the core body temperature of 37° C. The body sustains this temperature by balancing the heat generated within the body and the transfer of heat from body to the environment.

Working in hot environments causes strength to decline, and may result in fatigue sooner than it would otherwise. It may also affect alertness and mental capacity.

Effects of heat exposure on healthWhen the body is unable to loose heat as required through the evaporative cooling procedure to maintain a steady core body temperature, it starts experiencing physiological heat strain with several illnesses depending on the degree of heat stress.

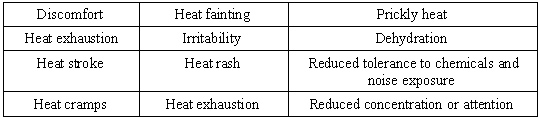

Some of the potential health effects for persons working under high heat stress environments include -

Heat cramps, heat exhaustion and heat stroke are the most severe heat illnesses. Heat stroke is a life endangering condition, which may result in permanent damage to the heart, brain or kidneys. Effects of heat stress are most likely to increase during the months of summer.

AcclimatisationPersons who regularly work in a hot working condition become acclimatised to a specific degree of heat. Acclimatisation reduces heat discomfort, increases the effectiveness of sweating, reduces salt loss and returns recovery rate to normal. Persons differ in their ability to acclimatise to heat.

Acclimatization provides only a partial protection from extreme heat and workers may still suffer from adverse health effects. Once the exposure to heat has discontinued, the protection from acclimatization is progressively lost. If a worker who has been absent from a hot work environment for a long period, such as a week; he should be first re-acclimatised to the hot environment for protection against heat related effects.

Factors regulating heat stressSome of the important factors that contribute to the heat problems are -

Factors associated with job- Work of an arduous nature

- Work, which is prolonged for extended periods

- Uncomfortable or awkward body position

- Insufficient cooling off or rest periods

Factors associated with the environment and season

- Extreme air temperatures

- Radiation heat from hot objects such as machinery

- Radiation heat from the sun if working in outdoors

- Higher levels of relative humidity

- Low air movement

Factors associated with workers

- Inappropriate clothing

- Level of acclimatisation

- Degree of adequate hydration

- Approachability to water and cool recovery regions

- Health condition e.g. heart, circulatory or skin disorders

- Medication, which impairs temperature regulation or perspiration (consult with doctor)

- Age and weight

- Level of physical fitness

- Insufficient salt in the diet

Control measures Elimination controls

The best control measure is to eliminate situations, which may result in heat related illnesses. This can be done by -

- Eliminating radiant heat sources that are not essential;

- Eliminating the sources of water vapor in the workplace (e.g. leaks from steam valves, evaporation of water from wet floors, etc.).

Modifying the work environment

Several control measures, which have found to be effective in preventing or minimizing the vulnerability to risk by reducing heat in the workplace include -

- Reducing the emissions of radiant from hot objects and surfaces (insulation and shielding);

- Altering the air temperature, air movement and relative humidity using local or general ventilation, spot coolers, fans, blowers and air conditioning;

- Reducing the metabolic heat production of body using automation and mechanization of tasks;

- Using ventilation e.g. setting flues extending from a foundry to the open air to ventilate cooling racks and fixed sources of heat; and

- Humidity reducing techniques (e.g. set a dehumidifier — seek engineering advice).

Administrative controls

Administrative controls generally include the development of safe working procedures and practices. Some of these controls are -

- Scheduling the hot tasks to cooler times of the day and maintenance to cooler seasons;

- Supporting the workers to take short breaks;

- Providing opportunity to the new workers or workers returning from holidays to acclimatize to the heat;

- Rotating workers to reduce the heat exposure duration;

- Programming routine work / rest breaks in cool, shady areas with protective clothing removed;

- Keep apart the hot work practices to times / locations distant from other workers;

- Use extra workers or ensure job sharing / rotation of workers;

- Workers with heart and blood pressure problems or previous heat illness should not be allowed to work in extremely hot areas.;

- Providing training to workers in the hazards related with working in hot environments, recognizing heat related illnesses, adopting safe work practices, control measures and the use and maintenance of personal protective equipment;

- Restricted consumption of diuretics (caffeinated drinks and alcohol);

- Access to sufficient supply of clean and cool drinking water; and

- Formulate a contingency plan for the treatment of affected workers.

Personal protective equipment (PPE)

Where heat exposure cannot be reduced or prevented by any other form of control, all exposed persons should be provided with personal protective equipment. Personal protective equipment used to prevent heat associated problems include -

- Eye wear, such as UV glasses

- Non-flammable and heat reflective equipment and clothing

- Water cooled bodysuits / vests and other equipment

- Protective footwear and gloves