Airborne Contaminants & Control Measures

Substantial concentrations of airborne contaminants can be found in various aspects of foundry operations. These contaminants can be found in several areas including pattern making, core making, mold making, fettling and sand plant regions.

The airborne contaminants in foundries are generally released from the -

- Preparation of scrap using heat and solvent degreasers (carbon monoxide)

- Melting procedure (carbon monoxide, sulfur dioxide, nitrogen oxide, chloride and fluoride compounds)

- Scrap handling (receiving, unloading, storage and conveying)

- Treatment and inoculation of molten metal prior to poring

- Core and mold making processes during sand reclamation, preparation and mixing of sand

- Mold and core forming processes, including core baking and mold drying from additives, binders and catalysts

- Cooling of casts causing decomposition of organic binders

- Casting knockout and shake-out

- Fettling

Along with these, airborne contaminants are also generated from various other foundry operations, including – furnace operations of melting and pouring carbon monoxide), cupola furnaces (sulfur dioxide), working of electric arc furnaces, treatment and inoculation of molten metal (dust), contaminants released during pouring (hot metal fumes), etc.

Gases & Vapors

Gases are formless fluids, which expand to occupy the space or enclosure in which they are enclosed. At normal temperature and pressure, true gases exist in the form of vapor. Many gases can be stored under pressure in liquid form until they are vaporized for use. These pressurized gases should be controlled in order to make the workplace air free from contamination.

Gaseous contaminants may also arise as a result of a chemical reaction or due to the breakdown of a complex chemical.

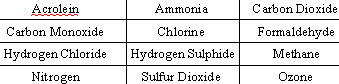

Some of the gases that are generally found in a foundry are -

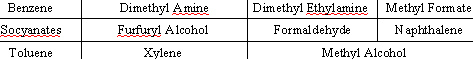

Some of the vapors that are generally found in a foundry are -

Gases and vapors are mostly invisible, however, some may have strong and characteristic smell, which may give the hint of their presence in a foundry. Instead, in some cases, the gases may have no such smell and may induce health problems at extremely low concentrations.

Gases and vapors are mostly invisible, however, some may have strong and characteristic smell, which may give the hint of their presence in a foundry. Instead, in some cases, the gases may have no such smell and may induce health problems at extremely low concentrations.

Some other gases show their presence through various irritating effects, such as coughing, respiratory irritation, asthma, acidic taste and watering of the eyes.

Dust & Fumes

Dust is particulate matter produced from solids and dispersed into the air due to the movement, loading, cleaning and handling of inorganic materials, such as metal, wood and sand. Fumes are airborne solid particles, which are formed as a result of the condensation of a material from a volatilized solid, generally molten metal in cool air.

The different types of dust and fumes that expose workers to various health risks in foundries are -

- Wood Dust

- Metal Dust

- Silica Dust

Control Measures for Airborne Contaminants

There are a number of control measures, which can be adopted alone, or in combination with other methods to prevent or minimize the exposure to risk.

Some of the general rules that can be followed to reduce / minimize airborne contaminants are -

- Replace silica sand with chromite sand.

- Adopt wet or vacuum processes instead of compressed air to minimize the creation of dust while removing loose dust or sand in the mold making method.

- Shut in major emission points, such as conveyor belt transfer areas.

- Set canopy hoods near the doors of furnace and the tapping outlets to seize contaminants and direct them through an emission regulation system.

- Supervise the carbon monoxide levels in the area of operation.