The automobile industry offers a huge market for the cast products using ferrous, non-ferrous metals and its alloys. Various casting methods are used to produce automobile accessories that are light in weight, easy to maneuver, and cheap.

Zinc Die Casting and Aluminum Die Casting are two most popularly used processes to produce automobile casting equipment.

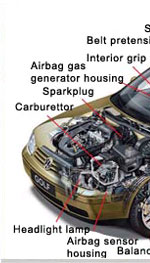

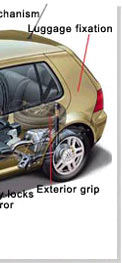

Zinc Die Casting : By using a method of Zinc Die Casting a host of automobile equipment can be manufactured as seen from the following figure:

Aluminum Die Casting : Automobile equipment are generally made of aluminum die castings. They offer the following benefits:

- Light weight, just one third of the weight of steel parts.

- Auto parts with aluminum can be cast net shape.

- Good production run with die cast auto parts produced in hundreds to thousands per day.

- Good thermal properties.

- Cheaper in cost.

Application of Aluminum Die Cast in Auto Parts

Numerous parts can be cast effectively using aluminum die cast like Valve covers, Wheels, Transmission housings, Engine block, Wheel spacer, Carburetors, Impellers and Fan clutch, Alternator housing etc.