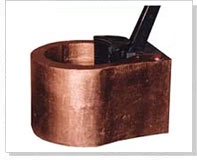

Cast copper is obtained after melting the metal and poured into different molds for getting the final or the desired casted shape. Casted copper is used for manufacturing a variety of products including handles, knobs, faucets, grates, sculptures etc.

Selection Process of Cast Copper Selecting copper alloys involves clearly analyzing materials grades and specifications. Compositional standards have been defined by The Copper Development Association (CDA) that adhere to the Unified Numbering System (UNS) for the various copper alloys. The system was established in conjunction with the Society of Automotive Engineers (SAE), the American Society for Testing and Materials (ASTM), and various other international metal trade associations.

There are various other organizations that define specifications for copper cast and wrought alloys including the Alloy Casting Institute (ACI), the Investment Casting Institute ICI), and the American Die Casting Institute (ADCI).

Copper alloy materials, which are manufactured in accordance with U.S. military specifications (MIL-SPEC) receive a QQ or QQS designation. Copper alloys that are suitable for aerospace applications meet criteria in the SAE's aerospace material specification (AMS).

Applications of Cast Copper

Cast copper is widely used for making different high quality and high

performance parts, components and products for use in diverse fields and

areas. Some of the fields where the metal alloy is used are:

- Architectural and building materials

- Automotive parts

- Automotive parts

- Household products

- Industrial fittings