The preparation of molten metal for casting is referred to as melting. It is usually done in a specifically designated area of the foundry, and the molten metal is transferred to the pouring area where the molds are filled. Melting may be done by gas or electricity. Various methods of pouring the molten metal are in use (e.g. gravity pouring, bottom pouring, vacuum or pressure assisted pouring).

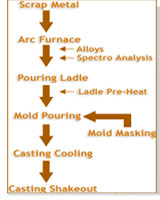

The melting process begins with the metal specification for the casting, determining the type of scrap metal to be used to 'charge' the furnace. Once charged, the furnace uses electrodes, each supplying roughly 6,500 amps of electricity, to melt the scrap metal. Samples are taken at various points in the melt process, to ascertain the chemical composition of the molten metal. Using a spectrometer as a guide, alloys are added to the furnace to bring the molten metal to the proper specification.

The melting process begins with the metal specification for the casting, determining the type of scrap metal to be used to 'charge' the furnace. Once charged, the furnace uses electrodes, each supplying roughly 6,500 amps of electricity, to melt the scrap metal. Samples are taken at various points in the melt process, to ascertain the chemical composition of the molten metal. Using a spectrometer as a guide, alloys are added to the furnace to bring the molten metal to the proper specification.

At a temperature of around 3,000° F the metal reaches the desired specification. It is then poured into a preheated ladle for transfer to the pouring lines. At the pouring lines, molten metal is 'poured' into the requisite molds. Due to the lifting pressure of molten steel, molds will often be 'weighted' or 'clamped' to prevent them from separating at the Cope/Drag meeting point. Thereafter, the mold is allowed to cool for approximately 30 minutes before it is taken to the shakeout. Poured molds are then dumped into a vibrating conveyor, wherein they are broken up by the vibration, exposing the casting for removal.

Finally the sand from the mold is separated and processed through a reclamation system for further use.