Blow Molding is otherwise called as blow forming which is a process in manufacturing. The process of blow molding is used for creating hollow plastics parts. The process of blow molding took its route from glass bottles making. In this molten glass which is collected in hollow pipes is expanded by blowing process through pipes. The polyethylene terephthalate enhanced the process of blow molding because of its attribute to resistance in making bottles from PET or other resins.

Types of Blow Molding : The types of blow molding which are three in number are discussed in detail below:

Extrusion Blow Molding : Extrusion Blow Molding is also denoted as EBM in short in which melting of plastic is done and the melted plastic is passed over a tube which is void and which is closed by a mold made of metal kept in low temperature condition. By blowing air over the hollow tube which causes the plastics to get the figure of the void container. After the shaping process is done the plastic is cooled. After sufficient cooling of the plastics is done the frame is unfastened to fetch the product.

There are various products, which get prepared by the process of extrusion blow molding. To name some in this direction are containers that we use in our daily life, shampoo bottles, pipes, and hoses and so on.

Types of Extrusion Blow Molding :

Extrusion Blow Molding has two major types associated in the process of blow molding. They are :

Extrusion Blow Molding has two major types associated in the process of blow molding. They are :

- Continuous Extrusion Equipment

- Intermittent Extrusion Machinery

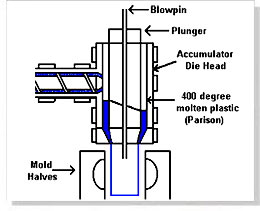

Injection blow molding : Injection blow molding is otherwise called as IBM in short takes its presence in manufacturing bottles and containers which are hollow apart from small medical bottles. Among the process used for blow molding injection blow molding method is the rarest used method. The process of injection blow molding has three major steps in it. They are the step of injection followed by process of blowing. The final step is the releasing of final product. In the step of injection the polymer is injected into core pin, which is then passed into blowing step where the core pin gets rotated to a blow molding station.

This is done to achieve inflation and cooling of the product. The final process is ejection in which the product is ejected. When the injection blow molding process is compared with extrusion blow molding the former takes high pressure.

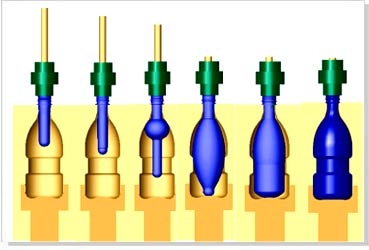

Stretch Blow Molding : SBM in short is one in which injection molded process is first used to get the plastic frame as a shape called as preform. The preforms have shapes, which include the top as well as the end part of the container.

These are then packaged and passed over extrusion blow molding. In the process of stretch blow molding, heating above the middle point within the range of temperature where the glass metastasis gets done is carried which results in performs. After this step metal blow molds are used for blowing intense air into containers. This is further put to the process of stretching.