Sand casting is a vital process in the process of castings. The process of sand casting has various steps and internal processes in it. Casting is the process in which the metal object is obtained by allowing molten metal to solidify in a mold. Metal casting is of utmost importance and popular since it is highly adaptable and could be used for handling mass production.

One of which is mold making. Mold making is a vital process in which a material is used for making the mold of the original model. Different materials can be used for mold making process depending on each one's needs and preference. The common material used for mold making process is the rubber.

Process of Mold Making:

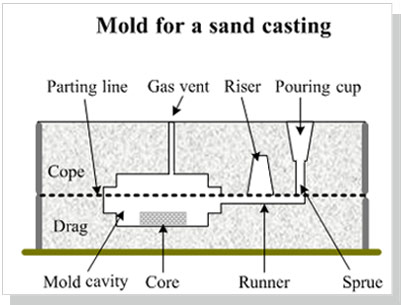

The mold flask is used as container for holding the mold. The mold flask is designed and separated into two halves to help in the process of mold making. The sand molds made are actually temporary molding. This results in the process of making new molds to carry out each individual casting of mold.

The sand mold is divided into two halves, which has the architecture and functionality as follows. The molding board holds the drag, which is nothing but the bottom, half of the mold. Since the molds are poured with greater force the cores must be of higher strength to handle the same.

The precision to be handled in the process must also be higher and so proper steps for handling higher accurate precision must be taken. This is because the surfaces which are interior are much difficult to machine. If proper steps are not taken for handling precisions of higher accuracy errors might crop inside.

The cores gets formed by various ways and one such way is by usage of chemical binding systems which is most popularly used in Canada. After inserting the core the cope, which is otherwise called as the top of the mold, is placed at the top portion. There is a parting line, which separates the two halves of the molding.

Since the attributes of metals keeps changing based on climate, weather and temperature conditions like expansion takes place during cooling its is essential to take proper steps and care to maintain the two halves in molding. One such step in this direction is to use weighting on top half of the mold.

The gating system presented in mold designs is used for smoother application of the molten metal. This help in even application of molten metal everywhere over the mold. The gating system carries out the process by the using tools like sprue, gates, runners and risers.

In the above the metal is poured in sprue and gates cause the metal to pass over the running system. This running system then carries the molten metal to the next process called as casting cavity.

The risers take up several functionality in the process of mold making To name some are releasing gases through vents, helps in process of solidification before casting of cavity by usage of reservoirs, reducing solidification problems by removal of first metal that gets poured into the casting cavity and handling waste cavities which helps in metal getting raised in cavity which further enhances solidification process.