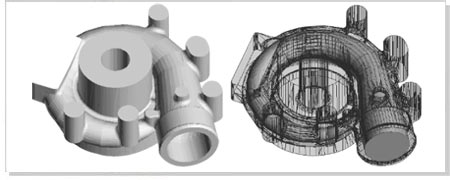

A Core is preformed sand aggregate, which inserted in a mold for shaping the interior part or that part of a metal casting that can't be formed by the pattern using any other process.

Since, core is an individual entity kept in a mold to produce a subsequent cavity in the casting in the form of a hole or undercut. They can be utilized to form pockets of complex shapes and special features that can't be produced using a pattern or a mold only. Cores may be expendable as used in sand casting or they may be permanent as used in die-casting. However, depending upon the shape of the core, which may be either simple or complex, permanent or expendable cores are used in gravity die-casting respectively.

A typical core consists of two parts. One is known as the body of the core and other is known as extensions also known as prints. Molten metal encloses the body of the core during the process of casting. Higher temperatures are maintained for longer durations inside a core as compared to that of a mold. Conversely, it is easier to collapse the sand core once the casting has cooled and the progress of its cleaning is smoothening. The other part known as prints is required to sustain the core within the mold. They also produce the heat and gases inside the mold.

In sand casting process, the cores are manufactured by wadding special purpose sand in the core-boxes. Depending upon the kind of application, cold- box, hotbox and oil sand is used for production processes of the core. Manufacturing of the core-box requires developing two segments to enable the withdrawal of the core. By assembling or gluing multiple cores of simpler shapes, composite cores are manufactured. Since core-related manufacturing processes requires significant costlier resources. Hence, the amount and quantity of the cores utilized must be minimized to the minimum level, to minimize overall cost and production time.Undercuts can be recognized on the basis of the direction of normal face in reference to the draw direction of segments of the mold. Other features of the core required to be identified are:

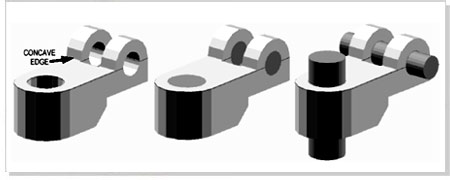

Edge recognition : An edge can be identified depending upon the internal angle between the two adjoining faces sharing the edges. These edges can further be classified in two categories as smooth edge, convex and concave edge. A smooth edge has an angle of 180 degrees and an edge with the angle less than 180 degrees represent convex edge. A convex edge is also known as external angle. However, an angle greater than 180 degrees represents concave or internal edge.

Hole Identification : A hole can be identified as a set of faces each of which has minimum of one concave or internal edge. The opening of the hole comprises of a closed ring of convex edges.

Undercut Identification : If the angle formed between normal facets in respect to the draw direction having that facet itself is less than 90 degrees, then this face is said to form an undercut.