A concept can be defined as a model or an idea, gradually developed on the basis of various studies, practical examples and nature of desired output. With a vision, that the proposed idea will be implemented and will achieve the desired target within the given timeframe. Concept development helps in analyzing and evaluating technologies to form the basic structure to some extent. A concept can be represented in the form of flowchart, block diagrams, textual figures. However, the supporting details to model the concept should be realistic so that the procedure of the concept is ensured.

Some design begins with the small idea which is lately developed into the final product and some concepts are naturally generated while understanding the engineering requirements of the development phase of the production plan. Former approach proves to be a weaker theory and it has been observed, that quality time is wasted in developing design concepts. However, the later theory helps in generating multiple concepts.

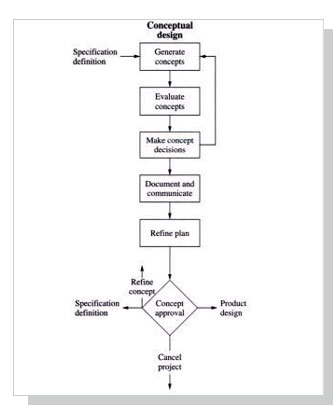

Fig 1.1- The conceptual design of the design process

Hence, the techniques used to develop the design must focus on integrating the issue to an extent of generating alternate solutions. The methodology should expand the design issue to many more branches before it is tapered to one final solution.

Understanding the functionality of various components involved in designing of the product requires combining devices which have similar functioning. Also, function is associated with the action of the product and form refers to the activity behind the actions. The functions of a component must be in a logical order. In performing these functions, the role of design engineer would be to provide guidance and energy in controlling the movement of the component. These functions are classified by the type of energy and the actions on the basis of energy flow. And the energy involved is mainly mechanical, thermal, fluid or electrical. Further the functions due to flow of such energies are categorized into through flow, diverging flow and converging flow. Through flow is associated with the material changing its shape and structure, diverging flow is related with dividing the material into sub parts. However, converging flow is related to joining of the materials.

Following steps help to understand the functions in a better way:

- The flow of energy, material and information determines the function of a system. Hence, the in and out flow of these energies are required to be analyzed to understand the whole process.

- By eliminating a component from the apparatus and then understanding its affect on the whole system

- To understand the working principle of transforming forces and energy flows of the complete unit, each interface of the component is examined carefully.

However, after understanding the functions, a technique to develop these functions is required to be drafted. This can be achieved with following steps:

- to identify the output requirements as per the customer specifications

- Divide the objective identified into sub objectives. This helps in searching for alternate solutions for the designing the problem. Further, dividing these sub functions into more detailed structure, gives more understanding of the concept. And separating the functions of the design may give a better solution for finding opportunities within the existing set of components.

- Splitting the sub objectives to finer details till an understanding of using the existing components over requirement of new components is attained.

After framing the concept into logical expressions, the design engineer works in collaboration with other industrial designers and marketing team. Together, they direct the design efforts into successful project and keeps a check on the updates and modifications required throughout the production.