Fused Depositing Model, which is otherwise called as FDM is a kind of rapid prototyping technology. This is used in the conversion of the CAD drawings into parts.

As we all know that rapid prototyping is nothing but the method of making three-dimensional (3D) models directly from CAD images. This technology was developed by S.Scrott Crump in late 1980's and was commercialized in 1990. This is marketed commercially by Stratasys Inc. FDM uses rapid prototyping technology of choice 2002, because of its high strength 3D CAD models, chrome plating drilling and sanding .It is also very easy to use.

Advantages of FDM Technology :

FDM technology is used widely because of the following advantages.

- The FDM material produces CAD Models that are dimensionally stable, so the parts have a long life cycle.

- They are both chemical as well as water resistant. They also provide 3d models made of production grade ABS plastic.

- Since the final product gives strength and durability, FDM is an excellent variety for any 3D Model.

- The FDM process can increase the build time and it requires support during the prototype building process.

- 3D prototyping can be used for building architectural models.

- FDM prototypes are the perfect choices among the engineers, designers, researchers, students and in other areas where rapid prototyping is used.

- It is one of the cheapest methods of producing plastic abs models and prototypes.

- Organic and complex geometric shapes and models can be easily and quickly created using FDM Printing.

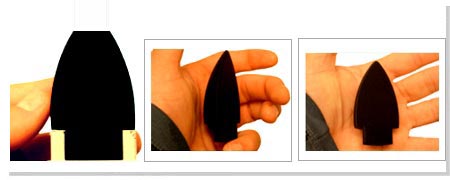

- FDM plastics are available in different colors like Black, White, Red, Yellow, Green, Blue, and Gray.