The flowing of molten alloy during casting procedure is a temporary phenomenon. It includes the following process.

- Splashing,

- Flowing through contracting

- Flow breakup and rejoining,

- Flowing against the forces of viscosity,

- Surface stress,

- Clash and seriousness,

- Atmosphere ambition and entrapment,

- Mold corrosion,

- Alloy oxidation

- Onslaught of solidification.

Let have a look on the major 2 issues. They are

- Instantaneous alloy speed

- Overall filling moment.

To improve the geometric analysis of mold filling, it is separated into three phases:

- Gating line filling,

- Dissolve flow impinging on the mold fence

- Mold cavity filling.

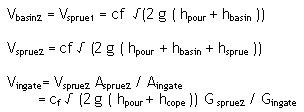

Let us assume that the gating channels have been designed correctly inorder to avert flowing breakup and surface instability, the velocities in different sections of the gating channels are given by the following equations.

G sprue / Gingate the sprue and ingate terms. The subscripts 1 and 2 refer to entry and exit cross-sections, respectively. The above-mentioned equation can be applied only for ingate speed in the top gating .The ingate speed decreases if they are located in the bottom or side. In such cases the equation is as follows:

hi - instantaneous vertical distance of alloy above the plane of ingates. Based on the Velocity of molten metal the filling time of entire gating system can be calculated. The molten metal flowing first can be hot and fast which can erode the mold wall. The instantaneous speed Vi of molten alloy after emerging from the ingate can be calculated by

The alloy flow is assumed to be along the axis of the ingate.The flow can be calculated taking tiny increments of moment, finally giving the position and instruction of impingement. At the level of impingement, mold harm can be caused due to the following mentioned reasons:

- The velocity of the impingement is higher than the critical speed for the mold material

- If the critical value is less than the angle between the direction nim and normal nf

A simplified way to determine the overall filling moment is determined by assuming that the casting fills layer-by-layer. The time required to fill layer is given by:

Ai - Filled cross-sectional area of the casting

h - layer thickness

Vingate-j Aingate-j -cross-sectional area and the instantaneous velocity of ingate j

Vingate-j Aingate-j -cross-sectional area and the instantaneous velocity of ingate j

The phenomenon such as splashing, rejoining of streams and branching cannot be found using the above method. It requires determining the velocity components along the three axes.