If you are practical minded, like to build things from scrap, and also enjoy creative challenges, then you can enjoy the personal rewards of the ancient craft of metal casting.

Armed with the right knowledge, it is quite practical to melt and cast metal in the home workshop, thousands of hobby metal workers the world over are involved in it right now... there's no reason why you could not try your hands at hobby metal casting too.

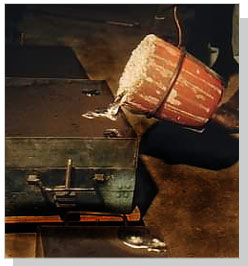

Your enjoyment will start right from the moment you start building the simple equipment required. It is possible to create amazing things with hobby metal casting. Proper understanding of the basic foundry knowledge, and simple equipment are the primary keys to the success of your hobby metal casting efforts.

What can be made in a home foundry? You can virtually create all kinds of things, with the only limiting factor is your skill – imagination – determination – passion. Foundry activities are fairly basic, you can use a timber or metal pattern to produce a cavity in a two-part sand mold, then carefully pour molten metal into the mold cavity. The more you learn and practice metal casting, the better your skills – work and creativity will become.

You can virtually create all kinds of things, with the only limiting factor is your skill – imagination – determination – passion. Foundry activities are fairly basic, you can use a timber or metal pattern to produce a cavity in a two-part sand mold, then carefully pour molten metal into the mold cavity. The more you learn and practice metal casting, the better your skills – work and creativity will become.

- Simple ornamental knobs & handles

- Hand wheels for small machinery

- Property nameplates

- Simple art castings, statues etc

- Unobtainable parts for restoration projects

- Vintage car & Motorcycle parts

- One off special project parts

Basic Mechanics of Hobby Metal Casting

To achieve success in metal casting, a hobby metal worker should first have to read, and learn the basics of hobby foundry so that he knows -

To achieve success in metal casting, a hobby metal worker should first have to read, and learn the basics of hobby foundry so that he knows -

- What metals can be melted?

- How to carry out the molding and casting operations?

- How to build the equipment & tools required to carry out this fascinating, ancient, metal craft?

You do not need an elaborate workshop to design your hobby foundry equipment. However you do need to have some welding skills, and knowledge to work with steel. A hobby metal worker may be involved with fabricating & welding, but regular workshop skills should get him up and running. You may even take the help of a close friend for any skills, which you may lack.

There is a great demand for things made by hobby metal workers for all kinds of different reasons. The primary reason for this is generally the desperate need to reproduce an obsolete part for a restoration project, and when you think about it, it actually makes sense, if a part was earlier made using the green sand casting method, then nine out of ten times, it can be recreated again using the same method.

Learning the technicalities of hobby metal castingThe best way to learn the art of metal casting is to have, or arrange for someone to train or coach you over a period of time in your own small foundry. Practical coaching helps quickly to learn the techniques to create sand molds, and many other things which you need to know.

You can also learn the skills of hobby metal casting from the numerous ebooks available on Internet. These ebooks help in learning the basics of metal casting and show practical methods to recreate castings from bronze or aluminum. The basic skills & methods that these ebooks explain, have been successfully used by many people who have never before tried their hand at metal casting. The metal casting process is not difficult to learn, and once you understand it, the only limiting factor is your imagination.

Safety AspectsIt is important to note that metal casting is dangerous, and injuries can result from carelessness. Do not attempt metal casting, if you have no prior experience or knowledge in this first. The first things you should do is to learn the basic techniques and methods used in this ancient metal craft.

As the metal casting requires you to handle molten metals at extremely high temperatures, there are many safety aspects to consider. With a sensible approach to safety, and by being extremely careful, accidents should not happen.