Pressure die casting is a quick, reliable and cost-effective manufacturing process for production of high volume, metal components that are net-shaped have tight tolerances. Basically, the pressure die casting process consists of injecting under high pressure a molten metal alloy into a steel mold (or tool). This gets solidified rapidly (from milliseconds to a few seconds) to form a net shaped component. It is then automatically extracted.

|

Types of Pressure Die Casting

| High Pressure Die Casting | Low Pressure Die Casting |

Depending upon the pressure used, there are two types of pressure die casting namely High Pressure Die Casting and Low Pressure Die Casting. While high pressure die casting has wider application encompassing nearly 50% of all light alloy casting production. Currently low pressure die casting accounts for about 20% of the total production but its use is increasing. High pressure castings are must for castings requiring tight tolerance and detailed geometry. As the extra pressure is able to push the metal into more detailed features in the mold. Low pressure die casting is commonly used for larger and non-critical parts.

However, the machine and its dies are very costly, and for this reason pressure die casting is viable only for high-volume production.

High Pressure Die Casting

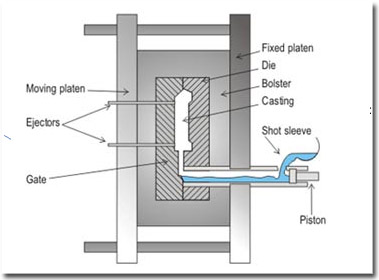

Here, the liquid metal is injected with high speed and high pressure into the metal mold. The basic equipment consists of two vertical platens. The bolsters are placed on these platens and this holds the die halves. Out of the two platens, one is fixed and the other movable.

This helps the die to open and close. A specific amount of metal is poured into the shot sleeve and afterwards introduced into the mold cavity. This is done using a hydraulically-driven piston. After the metal has solidified, the die is opened and the casting eventually removed.

Types of High Pressure Die Casting:

Both the processes are described below. The only difference between the two processes is the method being used to inject molten metal into the die.

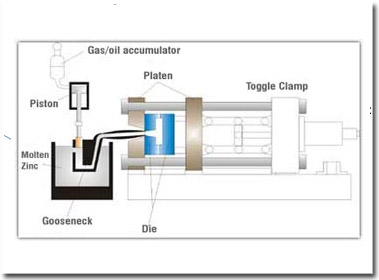

Hot Chamber Process

The hot-chamber process is applicable only for zinc and other low melting point alloys that does not affect and erode metal pots cylinders and plungers.

The basic components of a hot-chamber diecasting machine and die are illustrated below:

The workings of a hot chamber process goes like this. The molten metal for casting is placed in the holding furnace at the required temperature adjacent to(sometimes as part of the machine itself) the machine. The injection mechanism is placed within the holding furnace and most of its part is in constant touch with the molten metal. When pressure is transmitted by the injection piston, the metal is forced through the gooseneck into the die. On the return stroke, the metal is drawn towards the gooseneck for the next shot.

This process ensures minimum contact between air and the metal to be injected. The tendency for entrainment of air in the metal during injection is also minimised.

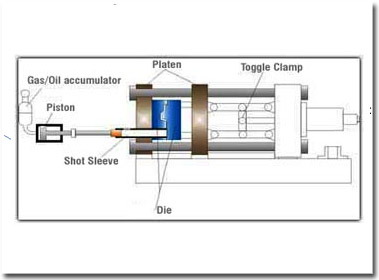

Cold Chamber Process

The difference of this process with the hot-chamber process is that the injection system is not submerged in molten metal. On the contrary, metal gets transferred by ladle, manually or automatically, to the shot sleeve. The metal is pushed into the die by a hydraulically operated plunger. This process minimises the contact time between the injector components and the molten metal. Which extends the life of the components. However the entrainment of air into the metal generally associated with high-speed injection can cause gas porosity in the castings. In the cold chamber machine, injection pressures over 10,000 psi or 70,000 KPa is obtainable. Generally steel castings along with aluminium and copper based alloys are produced by this method.

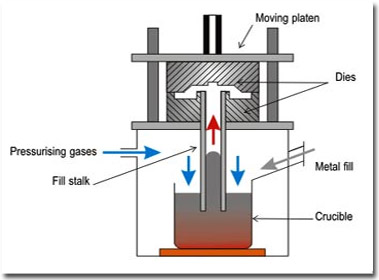

Low Pressure Die Casting

High quality castings, of aluminium alloys, along with magnesium and other low melting point alloys are usually produced through this process. Castings of aluminium in the weight range of 2-150 kg are a common feature.

The process works like this, first a metal die is positioned above a sealed furnace containing molten metal. A refractory-lined riser extends from the bottom of the die into the molten metal. Low pressure air (15 - 100 kPa, 2- 15 psi) is then introduced into the furnace. This makes the molten metal rise up the tube and enter the die cavity with low turbulence. After the metal has solidified, the air pressure is released . This makes the metal still in the molten state in the riser tube to fall back into the furnace. After subsequent cooling, the die is opened and the casting extracted.

With correct die design it is possible to eliminate the need of the riser also. This is because of the directional freezing of the casting. After the sequence has been established, the process can be controlled automatically using temperature and pressure controllers to oversee the operation of more than one diecasting machine.

Casting yield is exceptionally high as there is usually only one ingate and no feeders.

- Automotive parts like wheels, blocks, cylinder heads, manifolds etc.

- Aerospace castings.

- Electric motor housings.

- Kitchen ware such as pressure cooker.

- Cabinets for the electronics industry.

- General hardware appliances, pump parts, plumbing parts.