A crucible is a pot that is used to keep metals for melting in a furnace. Furnace crucibles are designed to withstand the highest temperatures encountered in the metal casting works. The crucible should essentially be made of materials with a much higher melting point than that of the materials to be melted. The crucible materials should also have good strength even when extremely hot.

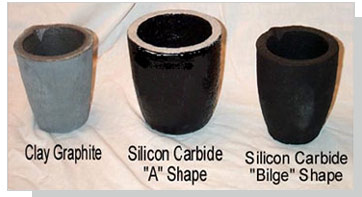

Furnace crucibles come in a variety of metal constructions, such as clay-graphite, silicon-carbide, and more. These materials can resist the extreme temperatures in typical foundry operations. Silicon carbide has the additional benefit of being a highly durable material. Some common shapes for crucibles include “A” shape and bilge shape.

It has been found that the "A Shape" crucibles are slightly rough around the edges. Their surface finishes are slightly coarse and there are dents and dings in the rims and body. These crucibles don't have as finished an appearance as the bilge types, however because of their lower price, many people prefer “A” type crucibles. The roughness does not affect the performance in any way.

Never stuffed a crucible with a cold metalNever filled the crucibles with a cold metal, such as aluminum – as there are strong chances that the metal will expand and crack the container. Also make sure to never allow the metal to solidify in the bottom of crucible, for the same cause.

Crucibles should properly be tested for cracks prior to each application. Replace the cracked crucibles with new ones. According to some hobby foundry professionals, a good ceramic crucible will "ring" when hit with a soft hammer while a damaged one will "clunk". Some people prefer a visual inspection.

Keep the crucibles in a dry place and pre-heat them and the metal to be melted as the furnace heats up. A little bit of moisture can cause the crucible to crack on heating.

Steel CruciblesHome made steel crucibles can be used to melt metals such as aluminum and zinc, because these metals melt a temperature well below that of steel. However flaking (scaling) of a steel crucible interior surface is a drawback. This scale can contaminate the melt and slender the walls of crucible rather quickly. Coating of marcote-7 can be applied to the crucible to provide some level of protection between the steel and the metal being melted.

Steel crucibles will work for starters in home foundry who don't mind dealing with the scaling.

Usage TipsThe crucibles should be handled with care using properly fitting tongs. Tongs are lifting tools that are used to protect crucibles from damage or failure.

Prior to heating, a plate of cardboard can be placed between the base of furnace and the crucible. The cardboard will burn off, thereby leaving a layer of carbon in between and protect the crucible from bonding to the furnace bottom.

It is better to use different crucibles for different types of metals to avoid contamination. Also make sure to completely empty the crucible after each use as the metal left to solidify may expand on re-heating, which may destroy the crucible.

The crucibles should be "tempered" before usage. Heat the empty crucible to a temperature of about 500 deg F. and hold it for 20 minutes. Then work the crucible to red heat. Turn off the heat and leave the crucible to cool slowly. This process takes off any moisture in the crucible. The crucible is now ready for use.

Place the material very loosely into the crucible. Do not pack the crucible, as the material will expand on heating and may damage the ceramic. When the material has been melted, carefully load more material into the puddle for melting (Warning - In the case, any moisture is present on the new material, steam explosion may occur). This time again, do not tightly pack in the metal. Keep adding the material into the container until the required quantity has been melted.

Make use of proper tools to transport and pour the melt. Use of safety equipment is essential as metal casting is an inherently dangerous activity.