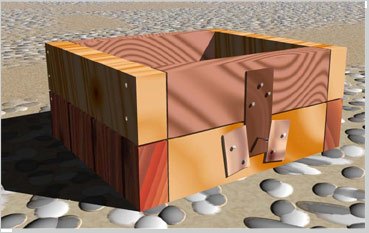

The casting flasks are made boxes made of wood that are topless as well as bottomless. These flasks fit together tightly from upper as well as lower side. If you have an adequate supply of 2" x 2" lumber and 3/8" plywood, you can make all all your flasks, so that each one is made of two halves, with 4 1/2" hight, and each comprising of plywood walls with the lumber at the corners to provide strength.

The casting flasks are made boxes made of wood that are topless as well as bottomless. These flasks fit together tightly from upper as well as lower side. If you have an adequate supply of 2" x 2" lumber and 3/8" plywood, you can make all all your flasks, so that each one is made of two halves, with 4 1/2" hight, and each comprising of plywood walls with the lumber at the corners to provide strength.

Plywood tapered tongues on both sides facilitate positive capture and positioning of the cope on the drag, keeping the alignment of sand cores between bottom and top. By offsetting the tapered tongues, you can make sure that the cope and drag will not be rotated with regard to each other. You can also drill a tiny hole near the bottom of the alignment tongue on either sides, through into the inner half of flask, by virtue of which you can lock the cope and drag together by simply putting the pins through these.

Use of drawer pulls on both the cope and drag has found to be good as it provides good and solid to hang onto, in the case you are trying to raise the cope off before rapping the pattern loose. By nailing some lath strips onto the inner sides of flasks, you can provide high positive retention to the sand, and a step for cross-ribs and gaggers if you are worried about the cope dropping out while lifting it.

Riffles and sieves:You can produce your own riffles for sifting sand onto the patterns. For a fine sand rifle, you can use a metal mosquito netting, and for a coarse backing rifle, you can use a 1/4" hardware cloth. Make use of the fine one for covering the wooden form in the beginning, until it has a good layer across overall form, and press it onto the form smoothly. Repeat the process a couple of times, prior to going to the coarse riffle.

To produce the flasks and riffles in matching sets, use 12 inches square fine and coarse riffle. Use 8" x 12", 12" x 18", and 12" x 24" flasks for monster castings. This will work well due to the fact that the riffle will sit firmly on the flask sides, providing them good support, while you are smashing the sand through the riffle mesh. It has also found to be good to use riffles that are designed with wood both above and below the mesh. The reason that this works so well is that the container on the top will hold the sand you are sifting, therefore it does not slop out over the top, and the space on the bottom will provide you additional clearance over the top of the mold, and hence the loose sand that you have sieved does not pack up to the bottom of the sieve as rapidly.